Blog

Cutting Through the Noise: Why Laser Cutting is Paving the Way for Australian Manufacturing

Cutting Through the Noise: Why Laser Cutting is Paving the Way for Australian Manufacturing

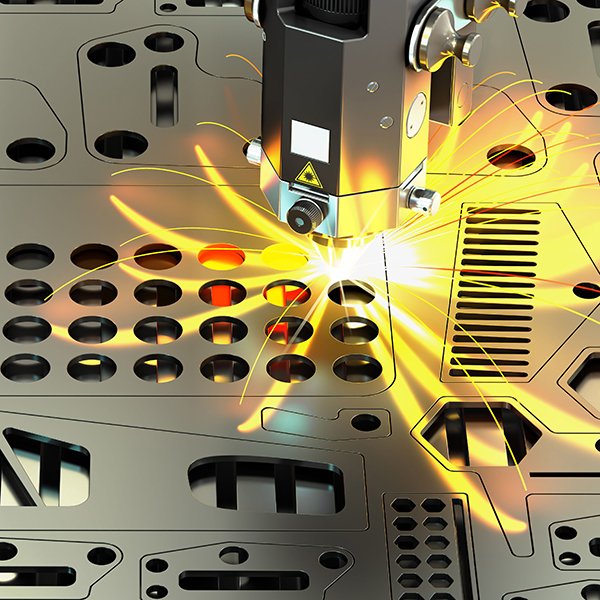

In the fast-paced world of Australian manufacturing, innovation and efficiency are the keys to success. As the industry continues to evolve, one technology is making a significant impact: laser cutting. With its precision, speed, and versatility, laser cutting is paving the way for a new era of manufacturing in Australia.

By harnessing the power of an intense laser beam, manufacturers can cut through a variety of materials with unparalleled accuracy. Whether it’s metal, plastic, wood, or fabric, laser cutting delivers clean, crisp edges without the need for additional finishing processes. This not only saves time and money, but it also ensures that every piece is manufactured to the highest standards.

But laser cutting offers more than just precision. With its ability to create intricate designs and patterns, it opens up a world of creative possibilities for manufacturers. From custom signage to decorative panels, laser cutting allows businesses to differentiate themselves and stand out in a crowded market.

In a competitive industry where every second counts, laser cutting is the tool that Australian manufacturers need to stay ahead. With its speed, precision, and creative potential, it’s revolutionizing the way we make things.

Advantages of laser cutting in manufacturing

Laser cutting has numerous advantages that make it a game-changer in the manufacturing industry. Firstly, its precision is unmatched. The laser beam is incredibly accurate, allowing manufacturers to cut intricate shapes and designs with ease. This precision leads to better quality products and reduces the need for manual corrections or rework.

Secondly, laser cutting is incredibly fast. The laser beam can cut through materials at high speeds, significantly reducing production times. This increased efficiency translates to higher productivity and shorter lead times for manufacturers, allowing them to meet customer demands more effectively.

Another advantage of laser cutting is its versatility. It can be used to cut a wide range of materials, from thin metals to thick plastics. This flexibility makes laser cutting suitable for a variety of industries, including automotive, aerospace, and fashion. Manufacturers can rely on laser cutting to handle different material thicknesses and types without the need for specialized equipment.

Find out more information here

Please contact me here for more information or you can read more about laser cutting here