Blog

Pushing Boundaries and Inspiring Design

The Endless Possibilities of Laser Cuts: Pushing Boundaries and Inspiring Design

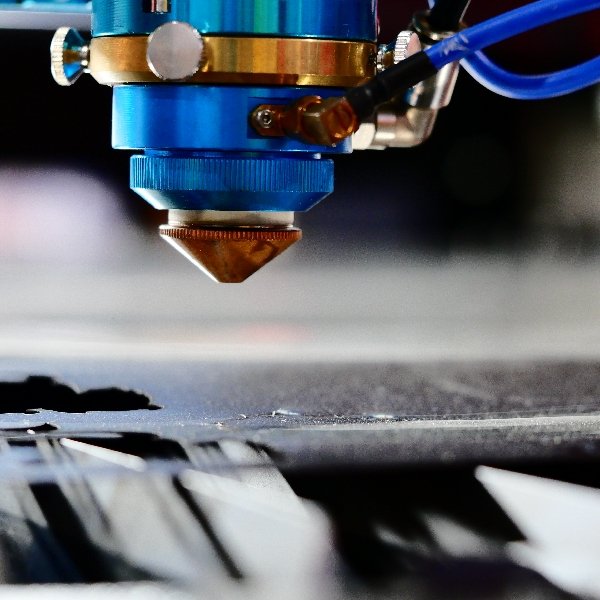

In today’s world of design and innovation, lasers have become an essential tool, pushing the boundaries of creativity and possibilities. Laser cuts, in particular, have emerged as a game-changer, revolutionizing the way we think about design and craftsmanship. From intricate patterns to precise shapes, laser cuts offer endless possibilities for artists, architects, and designers alike.

With the ability to effortlessly cut through a range of materials including wood, acrylic, and even metal, laser technology has paved the way for stunning and intricate designs that were once unthinkable. The precision and accuracy of laser cuts have not only elevated the quality of craftsmanship but have also opened up a world of opportunities for designers to experiment and create unique pieces that leave a lasting impression.

Whether it’s incorporating laser-cut patterns into furniture, fashion, or even architecture, these designs are captivating audiences worldwide with their intricate details and artistic flair. From intricately etched jewelry to beautifully patterned room dividers, laser cuts are turning ideas into reality with precision and elegance.

Join us as we explore the endless possibilities of laser cuts, how they are pushing boundaries, and inspiring design in ways never imagined before.

Design considerations for laser cut projects

When designing for laser cutting, there are several considerations to keep in mind to ensure a successful outcome. One of the key factors is the design’s suitability for the chosen material and cutting technique. Some designs may be better suited for certain materials or techniques, and understanding these limitations helps designers make informed decisions.

Intricate and detailed designs may require slower cutting speeds to achieve precision, while simpler designs can be cut at faster speeds. The thickness of the material also plays a role in determining the cutting speed and power needed. Thicker materials may require multiple passes or higher power settings to achieve a clean cut.

It’s also important to consider the kerf, which refers to the width of the cut made by the laser. The kerf varies depending on the laser cutting technique and the material being cut. Designers need to account for the kerf when creating their designs, ensuring that the final dimensions match their intended specifications.

Additionally, the use of support structures or tabs may be necessary to prevent small or intricate pieces from falling out during the cutting process. These support structures can be easily removed after the cutting is complete, leaving behind clean and precise pieces.

Find out more here

Please contact me here for more information or you can read more about laser cutting here