Tips and Tricks

Tips and Tricks

Laser Cutting Tips and Tricks

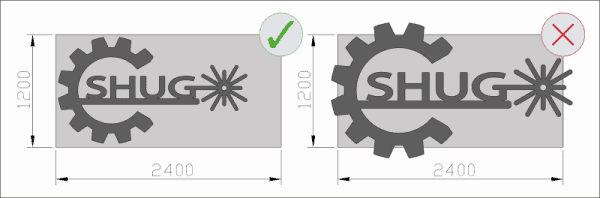

- As the maximum sheet size my laser can cut is 1200mm X 2400mm, all larger parts or artwork must fit within these parameters

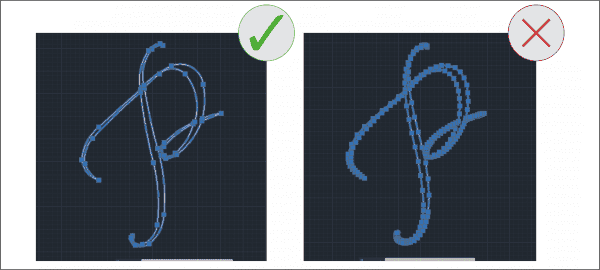

- Minimising nodes, vertex and lines, will reduce the cutting time. Multiple nodes, vertexes and lines will lead to an increase in time consumed to cut the design and therefore an increase in costs

- Eliminate jagged edges, as the laser cuts better with rounded curves and edges. Designs and artwork can be flawed through jagged edges, as this causes burning or blow outs.

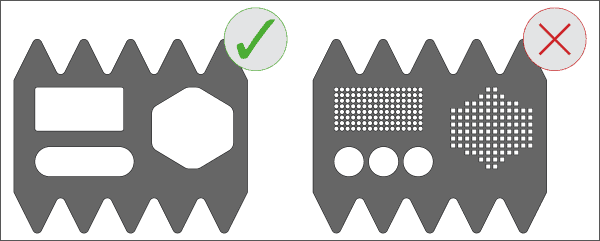

- Eliminate piercings or holes to minimise cutting time and costs. Unnecessary holes or cut-outs can be eliminated without compromising your design, therefore reducing costs.

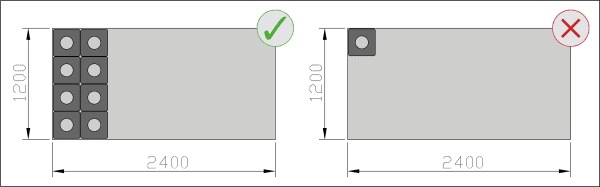

- Minimising costs can be enabled by cutting as many parts on one pass. Shug laser has a minimum charge of $66.00 including taxes. A cost example would be a square part 290mm X 290mm cut from 2mm mild steel, one part would cost $66.00, but cutting 8 parts would entail the exact same costs. Please contact me for a quotation prior to ordering, as the aforementioned example is not applicable to every order.

- As small parts have the tendency to appear enlarged in Design or CAD software, please ensure that all gaps in the design are correct, to prevent a blowout while laser cutting.

- Print a design at 1:1 scale prior to ordering, as this will give a true reflection of how the design will look before cutting.

- Ensure that parts under 3mm thick, have a minimum gap of 3mm and parts 3mm / 4mm thick, have a minimum gap of 5mm gap. Parts that are 5mm thick and over, should have a minimum gap of 6mm. The wider the gap the better for the design. Please contact me prior to ordering, if you are unsure and I can guide you to correcting your gaps to your part, before cutting is done.

- DXF files are not only the best files for laser cutting, but are also our preferred file format. For optimum results, DXF. format must be saved in an R14, R13 or R12. Should other software files, create more nodes and vertexes, when converting to DXF format, the client will be contacted, as this can lead to longer cutting times and higher costs. The file will be requested in its original format for example Ai.