Blog

What Is Laser Cutting? How To Cut Metal With A Laser.

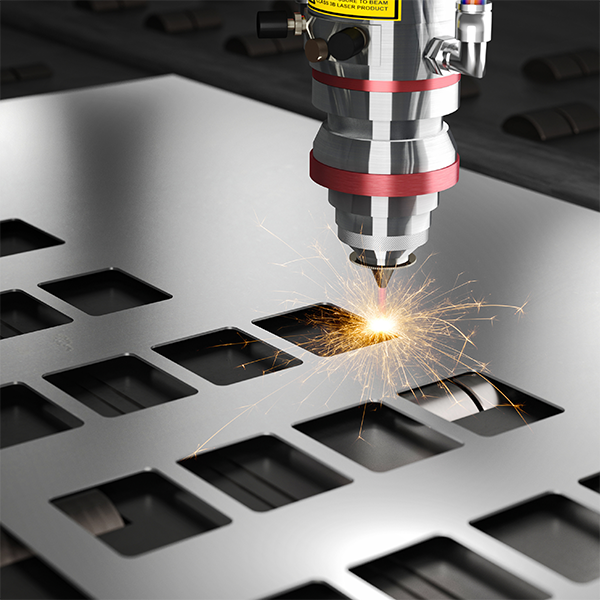

Unveiling the Power Behind Laser Cutting: A Metal Masterpiece in the Making

Introduction:

Ever wondered how metal can be sliced and diced with incredible precision and finesse? Enter laser cutting, the ingenious process that has revolutionized metalwork with its accuracy and speed. In this article, we’ll embark on an intriguing journey to uncover the secrets behind laser cutting and explore how it has become the go-to technique for fabricating metal masterpieces. So grab a cup of coffee and let’s dive into the world of laser cutting, where science meets craftsmanship!

1. The Science behind the Beam:

Laser cutting works by harnessing the power of a high-energy laser beam. This beam is emitted from a specially designed laser machine and primarily consists of concentrated light particles. By controlling the intensity and focus of the laser beam, metal sheets of varying thicknesses can be sliced through with astounding precision. We’re talking about cuts as narrow as a human hair!

2. Why Choose Laser Cutting?

What makes laser cutting the preferred method for shaping and sculpting metal? One word: accuracy. Whether you need intricate designs, complex shapes, or tiny holes in your metal piece, laser cutting offers unparalleled precision. Unlike traditional cutting methods, lasers eliminate the risk of human error and deliver results that are simply mind-blowing. From industrial applications to artistic endeavors, laser-cut metal has become synonymous with quality and precision.

3. Cutting Through Time:

Speed is another feather in the laser cutting cap. The process itself is incredibly fast, allowing for efficient production and quick turnarounds. These machines can cut through metal like a hot knife through butter, completing intricate designs in a fraction of the time it would take using conventional methods. Moreover, the lack of physical contact between the cutting tool and the material reduces the wear and tear on the equipment, enabling longer operational hours with minimal maintenance.

4. Material Matters:

While laser cutting can effectively slice through various metals such as stainless steel, aluminum, and brass, some materials require extra precautions. For instance, reflective metals tend to bounce the laser beam back, making cutting a tad trickier. However, modern laser machines come equipped with sensors and adjustments to mitigate these challenges. With the right settings and expertise, even the most demanding materials can be tamed by the laser’s mighty beam.

5. Safety First:

As with any powerful tool, safety is of paramount importance when dealing with laser cutting machines. Protective eyewear, dust extraction systems, and proper training for operators are essential to ensure a safe working environment. Additionally, laser cutting generates fumes and smoke, so adequate ventilation and air filtration systems are a must.

Conclusion:

Laser cutting has undoubtedly reshaped the way we create and manipulate metal. Its unbeatable precision, lightning-fast speed, and versatility have made it a vital tool in both industrial and artistic realms. As technology continues to evolve, we can only anticipate even more incredible advancements in laser cutting techniques. So next time you come across a meticulously designed metal masterpiece, remember that behind its flawless facade lies the powerful beam of a laser cutter.

Find out more here

Please contact me here for more information or you can read more about laser cutting here